One of my favorite things is sitting down with them, seeing what they really want and showing them how everything will look when it’s done.” “I’m very heavily involved with the customers, and even the contractors I work with turn customers over to me.

#Cabinet vision cnc full#

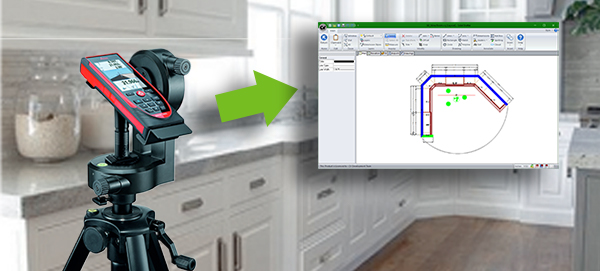

“With Cabinet Vision, I can put a design in front on my customer and they can see any changes that they want to make, and see the full layout of the project,” Vance says. He also encourages customers to submit images of finished spaces that they find aesthetically pleasing, which gives him an idea of their style preferences. Jobs at Alexis begin when Vance visits the homes of customers to look at the spaces in which his projects will be built. It’s helping my business go to the next level.”

#Cabinet vision cnc software#

I’m extremely pleased with the software I have no regrets or buyer’s remorse. “I can just hand the drawings and the sheets to my employees and they’re able to go from there, without more help from me. “I hand him drawings and everything he needs is on the cut list and the assembly sheet, so having the software has really helped him to understand how things work,” Vance says. Though small, his team is able to take on more work while maintaining high product quality, making fewer errors, and dealing with shorter lead times.Ī former employee of Vance’s returned to the job after the implementation of Cabinet Vision and was almost instantly farther along in his ability to understand the flow and logistics of production than he was when he’d left. Since implementing Cabinet Vision, Vance has hired a new full-time employee, which brings his crew up to three, including his wife, Sheila, who works in the shop part time.

Just in labour, I’ve paid for the software twice - and I’ve had it for less than six months.” I started looking at what my hourly rate was versus using software, and the difference was very significant. “I was going through and hand figuring all of my boxes and all of my cut lists,” he says. After investigating his options, he purchased the Cabinet Vision design-to-manufacturing solution in the summer of 2017. To take his business to the next level in overall efficiency and production capacity, Vance needed software that could generate realistic shop drawings, as well as material and cut lists. “In giving our customers what they want, a high level of service is very important to us.”

“We’re building the kind of quality products that you can’t get without going completely custom,” says Vance, who attracts new clients primarily by word-of-mouth. Today, Vance is owner of Alexis Cabinet Works, a custom high-end residential shop based in Iron Station, North Carolina, that prides itself on delivering top-notch quality and customer service. Woodworking began as just another summer job for Vance Sadler, whose first stint in a woodshop turned quickly into a passion and ultimately a career path. High-end residential woodshop Alexis Cabinet Works increases volume and shop-floor efficiency with Cabinet Vision’s job-management tools

0 kommentar(er)

0 kommentar(er)